Centralised plant control and 3D Digital Twin Visualisations

Yahong Bridge and Hejian Water Authorities are local authorities that own and operate a number of waste water treatment plants.

Our Strategy

CT started the project by upgrading the client’s legacy plant PLC’s to Siemens Simatic S7’s and KingSCADA, bringing them up to the latest and supported versions.

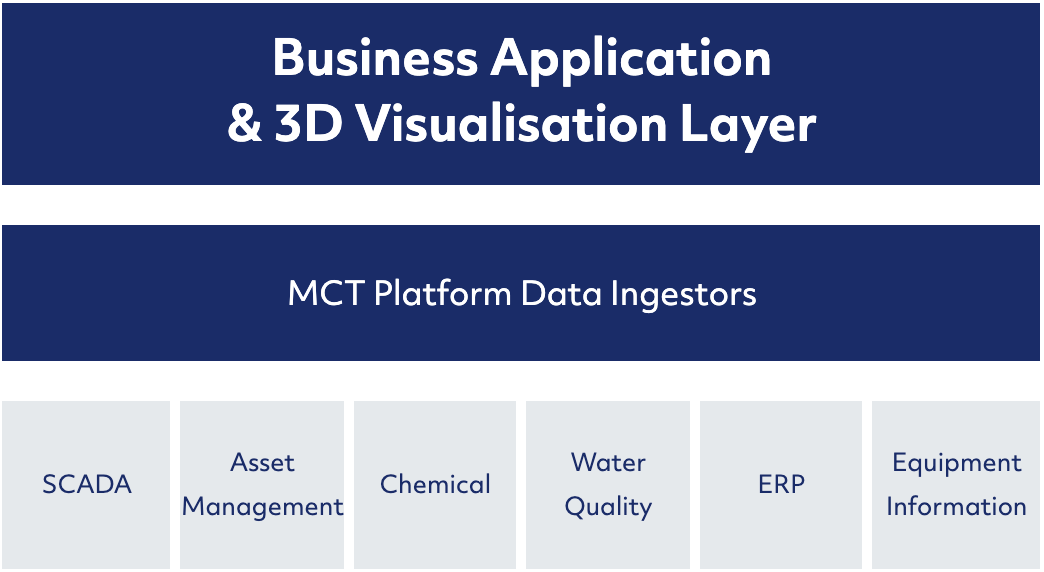

The project then moved on to centralising all related plant operational system data into the MeridianCT IoT Platform, which included SCADA, Asset Management data, Chemical and Water Quality Systems data.

3D Digital Twin Visualisation Layer

The MeridianCT platform supplemented the SCADA systems through ingesting and integrating the existing plant operation systems. The advanced 3D Digital Twin visualisation layer, provides the most intuitive and comprehensive view of all integrated plant operations, allowing for remote inspections, ‘fly-arounds’ and ‘look-throughs’ and the ability to visualise operating equipment status, water quality, sub-terranean pipe work and hydraulic flows.

Process Driven

To optimise business workflow, CT utilised the integrated plant operations systems data within MeridianCT Platform to provide users with the ability to select and control equipment from within the 3D Digital Twin visualisation, retrieve maintenance history, specification sheets, O&M manuals, check on critical spare holdings, raise purchase orders and work orders, all without leaving the platform.

Every aspect of the working plant is covered, including the ability to instantly display historical trend data of each part of the entire

Machine Learning

Striving for continuous business improvement, CT developed customised machine learning algorithms utilising the aggregated and contextualised datasets to derive plant optimisation opportunities, reduce equipment downtime, improve energy usage and process outcomes.

Transformation

CT1 has deployed this solution across five Water Treatment plants to date. The highly functional MeridianCT platform with interactive advanced 3D visualisation layer and centralised plant control has:

Improved safety and responsiveness across operations

Streamlined communication and information sharing between control rooms and plant operations staff

Optimises plant, process and resource use, including maintenance and staff management workflows